Metering & Sampling Solutions

Metering & Sampling

- Flow Computing

- Custody Transfer

- Packaged Analyser Systems

- Metering Skids

- ISO10723 EffecTech

- Emission Monitoring Systems

- Validation

Flow Computing Capabilities

Synertec has a team of highly experienced metering engineers implement innovative, cost effective metering control systems compliant to international standards such as ISO9001:21025 and API MPMS Chapter 21.

Focussed on Outcomes

Synertec has been working in the oil and gas industry for over 20 years with a diverse service offering nd has in-house design, development, commissioning, and consultancy skills and capabilities. We are an experienced metering system integrator in Australia with a deep understanding of project execution, site supervision, and requirements for Occupational Health, Safety, and Environment (OHSE).

Track Record

Synertec has provided metering systems and services to many operators including Chevron (for both Gorgon and Wheatstone), Woodside, Eni, INPEX Corporation, Lochard Energy, and Jemena. Synertec’s in-house metering team have development experience with a wide range of flow computers including:

- Emerson FloBoss S600/S600+

- Emerson ROC800

- ABB Flow-X

- Krohne Summit 8800

- EXI SCF3000

- Honeywell RTU 2020

- Emerson Control Wave Micro

- OMNI 3000/6000

In addition to the above, Synertec can deliver specially designed Human Machine Interface applications using industry standard Supervisory Control And Data Acquisition (SCADA) software including:

- Rockwell

- Siemens

- Schneider

- OMRON

- GE

- ABB

- Honeywell

Relevant Experience

Synertec has a strong track record designing and delivering metering projects over our 20 year history. We have developed an ISO 9001 certified project management system covering change management, regulatory compliance, quality, schedule, and cost, which has allowed for delivery of projects throughout Australia.

Additional Services

Synertec can provide additional services including:

- Front End Engineering Design (FEED) Studies

- System audits

- Uncertainty analysis

- Maintenance work instruction development

- System support

- System health checks

- Training

- System installation, commissioning and start-up

- Obsolescence management

- Patch validation

Custody Transfer Capabilities

In the Oil and Gas industry, Custody Transfer refers to the metering of a transfer of fluid or gas from one party to another, where the amount of product is measured with a high degree of accuracy. The total transaction price is then calculated based on the price per given volume. With the enormous quantities often transferred in these transactions, the need for accurate measurement is paramount. The tiniest of errors, even in fractions of a percent, can quickly add up to millions of dollars.

Custody transfer can be marine-based, occurring between tanker ships, or land-based, between ship and shore.

As Liquefied Natural Gas (LNG) sales agreements continue to evolve to meet the expectations of a changing supply and demand market, producers and buyers are insisting on higher precision, greater reliability, real-time cargo release, and compliance with recognised international measurement standards.

Traditional custody transfer systems are being challenged to meet these requirements. Synertec’s LNG custody transfer system is certified by the National Measurement Institute (Netherlands) and EffecTech (UK), complies with the requirements of the International Group of Liquified Natural Gas Importers, and is compliant with ISO 8943 and ISO 6974. Combined with a 99.98% correlation with laboratory calibration measurements, this ensures the most precise measurement of loaded LNG.

Our proprietary custody transfer system has been proven under the most demanding field conditions to provide a substantial return on investment, has earned accolades from some of the world’s biggest LNG operators, and provides the following significant benefits:

- Improved profits

- Improved cashflow

- Reduced (if not eliminated) disputes

- Reduced (if not eliminated) reliance on laboratory testing

Track Record

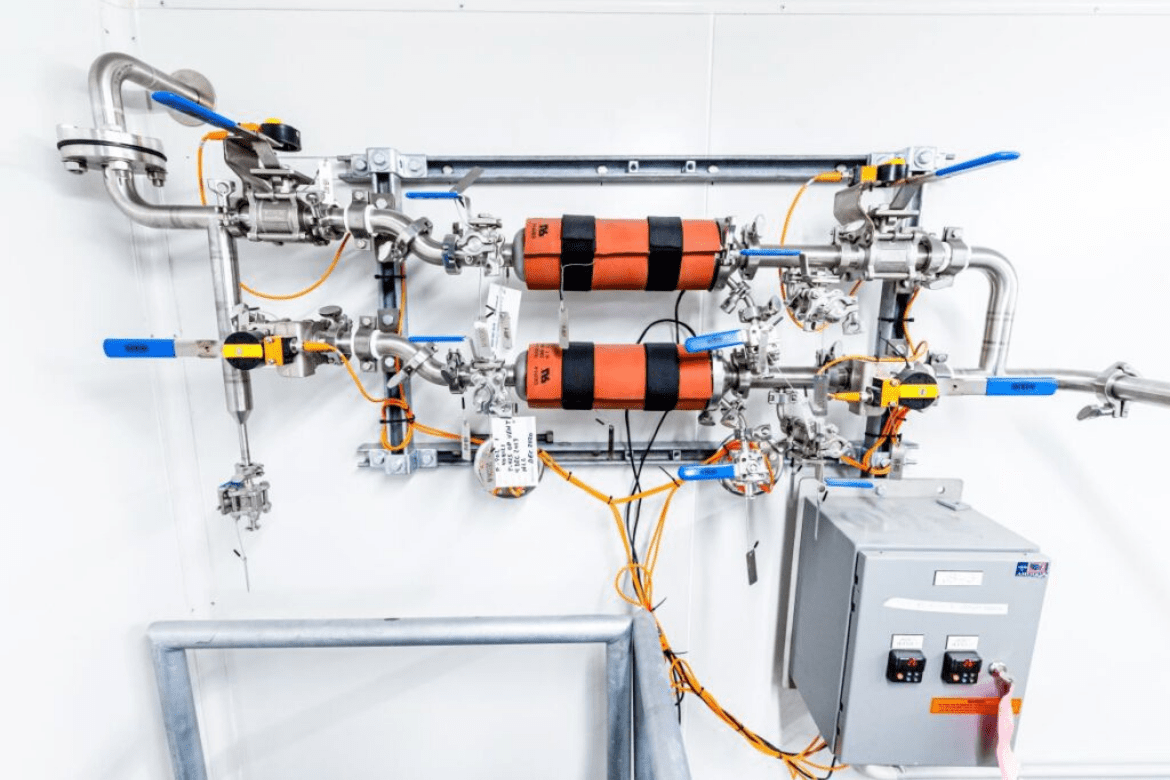

Synertec’s Custody Transfer System is a skid mounted module suitable for all LNG applications including onshore, shipboard, and floating LNG installations. Synertec is dedicated to meeting customer needs and offers its valued clients flexible procurement options tailored to specific requirements. For example, Synertec can offer the system on a lease arrangement with no money paid until the system is installed on-site.

Our custody transfer system is suitable for both high-pressure and low-pressure LNG process systems. Our designs and builds are certified to CE European Standard requirements, and all major ship classifications including Det Norske Veritas (DNV), American Bureau of Shipping (ABS), and Lloyd’s Register (LR).

Click here for more information on our LNG custody transfer solutions.

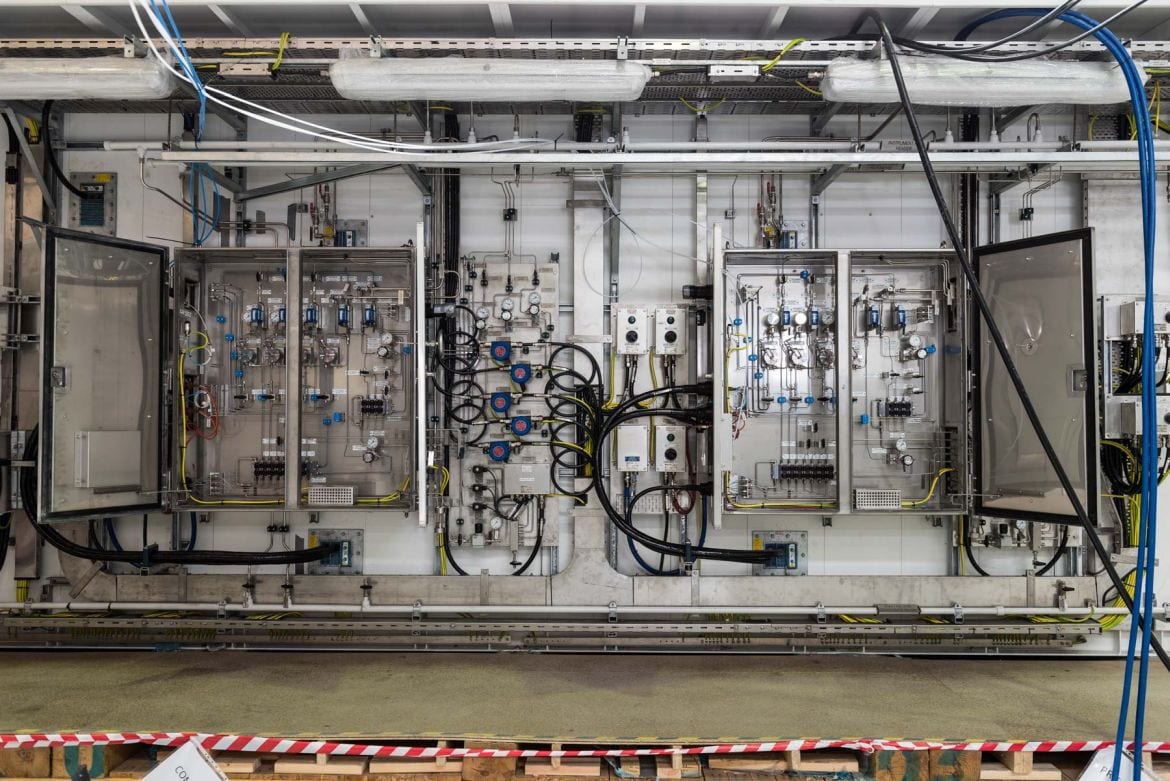

Packaged Analyser System Capabilities

The use of online analytical instruments is becoming more and more important as customers strive to increase the quality of goods, reduce costs, and meet regulatory requirements. Synertec can provide vendor independent engineering services to ensure the total system meets all requirements and achieves high value for money outcomes.

A successful implementation can be assured by using Synertec to provide a complete end-to-end solution.

Focussed on Outcomes

Implementing a reliable packaged analyser system is a complex undertaking that is about so much more than simply choosing an analyser. The success and ongoing reliability and accuracy of the measurements require holistic integration of the entire system. This includes the design of the sample probe or extraction system, sample transport, conditioning and phase control, presentation to the analyser, and then finally the safe and environmentally responsible disposal of the sample.

Synertec has the analyser system experience to ensure this is incorporated into every instrumentation system design. We design and build gas chromatograph systems, analyser houses, and flow computers to gather this key data. To ensure ongoing accuracy of the system, Synertec can perform validation and calibration services, including ISO10723 performance evaluation on all instruments.

The analyser environment plays a major role in the reliability of an online analyser solution. Synertec can specify, design, and build a suitable and cost effective solution for any environment. Typical approaches include a simple cabinet, an intermediate shelter, or a complete housing, for either safe or hazardous environments.

Track Record

Synertec provides services for the following typical applications:

- On-line Gas Chromatography for natural gas, Liquefied Natural Gas (LNG) and hydrogen

- Custody transfer

- Continuous Emission Monitoring Systems (CEMS)

- Hydrogen cooled generators

- Gas purity

- Calorimeter systems

- Physical property analysers

- Humidity Systems

- Infrared analysers

- Wet racks

Synertec’s systems can be certified to CE European Standard requirements, and all major ship classifications including Det Norske Veritas (DNV), American Bureau of Shipping (ABS), and Lloyd’s Register (LR).

Our team are experts in hazardous area design and will ensure the system fully complies with relevant zone specifications.

Synertec have designed and built analyser systems for a range of projects including small scale metering skids, up to large scale LNG export terminals. Regardless of size, it is critical to deliver highly accurate sampling systems to ensure the quality of the sampled gas is completely representative. Major analyser installations include:

- Design and supply of 45 analysers including GC, CO2 and moisture analysers for Queensland Curtis LNG, including the design and build of 5 analyser racks and 8 analyser shelters

- Design and supply of six fully airconditioned analyser shelters with fire and gas systems for a Zone 2 hazardous area for Australia Pacific LNG. These shelters contained GC, Wobbe, moisture, CO2, O2, and water analysers, along with flow computers and LNG samplers

- Active ventilation and off-gas control system for a nuclear waste treatment facility at the Australian Nuclear Science and Technology Organisation (ANSTO) nuclear reactor facility at Lucas Heights

Metering Skid Capabilities

Synertec designs and builds metering skids for a wide range of applications including natural gas, hydrogen and Liquefied Natural Gas (LNG). Our team of electrical, instrumentation, process, and automation engineers work closely with our design and drafting team to provide a complete turnkey solution including piping, valves, meters, analysers, flow computers, shelters, and all ancillary services.

Focussed on Outcomes

With exposure to a wide range of highly regulated industries including Oil and Gas, Pharmaceuticals, Defence, and Bulk liquid terminals, Synertec have extensive experience in all aspects of pipeline engineering. We design and fabricate to all relevant standards including AS 2885 and ISO 13623.

Our team are experienced in the design and fabrication of metering skids, gas analysers, LNG analysers, instrumentation, and hazardous area design for both high-pressure and low-pressure applications.

Our engineers, designers, and drafters work closely together to create metering skid designs using smart packages such as:

- Plant 3D

- CADWorx

- Elecdes electrical CAD

- Revit

- Navisworks

Our in-house team of hazardous area and functional safety experts ensure all hazardous area and safety integrity level requirements are achieved.

Track Record

Synertec designs and fabricates entire metering skid packages including:

- Piping

- Valves

- Structural supports

- Instrumentation

- Flow meters

- Sample conditioning systems

- Gas chromatographs

- Gas analysers

- Flow computers

- Analyser housing

- Control panels

- Control systems

- Supervisory control and data acquisition systems

- Safety systems

Our metering skids can be built for the measurement and analysis of natural gas, LNG, or hydrogen using a range of meter technologies, including Ultrasonic, Turbine, Coriolis, and Venturi.

Relevant Experience

Our metering solution clients include:

- APA Group

- Australia Pacific LNG

- Beach Energy

- Bechtel

- Chevron

- ConocoPhillips

- Eni

- Gladstone LNG

- Inpex

- Jemena

- Lochard Energy

- Queensland Curtis LNG

Our systems can be built for land-based or marine-based (offshore/vessel) applications. These systems are accredited to the highest standards including CE marking, Det Norske Veritas (DNV), American Bureau of Shipping (ABS), and Lloyd’s Register (LR).

ISO10723 EffecTech

Headquartered in the UK, EffecTech is the global leader in gas measurement, providing accredited inspection, calibration and testing services to the energy and power industries for gas quality, flow, and total energy metering. Their highly trained and experienced staff provide fast and effective solutions to all gas measurement requirements. Accredited by the International Standards Organisation, the United Kingdom Accreditation Service, and the British Standards Institute, EffecTech is recognised around the world as a leader in their field.

Synertec is proud to be an EffectTech global partner and represent them in Australia by performing ISO 10723 performance evaluations around the country on their behalf.

ISO 10723 defines the methodology for performance evaluation of analytical systems used in the natural gas industry. The standard specifies the process for accurate performance testing of a Gas Chromatograph (GC).

The performance evaluations carried out by Synertec on a GC use at least seven reference gases of varying composition covering all the components measured by the GC under test. The GC is used to measure all the reference gases and the results are then sent to EffecTech, where the linearity and repeatability of the GC are established using regression analysis. Using these parameters, an offline model of the GC is developed to establish the magnitude of the errors and uncertainties when measuring the range of natural gas or Liquefied Natural Gas (LNG) passing through the metering point. These errors and uncertainties can be used to demonstrate compliance with contractual requirements or environmental regulations.

The results from the performance evaluation include response functions for all components, which can be applied to the instrument to correct non-linearity errors, assuring the highest possible level of accuracy.

EffecTech’s proficiency testing schemes provide objective evidence of analytical performance for both laboratory and process methods, which include participants from around the world including:

- Global Gas and LNG (GGLNG) for the natural gas and LNG industries

- Stack Emissions Proficiency Testing Scheme (SEPTS) for companies that provide stack testing services.

Emission Monitoring System Capabilities

With increased industrialisation come associated concerns with air quality. Industrial emissions have been an ongoing problem around the world for many years and concern continues to grow as health experts gain greater understanding of the short-term and long-term health effects of poor air quality. A key weapon in this battle is the strict environmental controls that limit allowable emissions from industrial activity. This is a requirement for many industries, particularly heavy industry such as Oil & Gas.

Maintaining accurate emissions records is a vital part of demonstrating compliance with regulatory requirements but also in the achievement of the operator’s own quality benchmarks, which may be better than the legislated minimum performance.

Emission Monitoring Systems provide the mechanism to constantly measure emissions accurately. Reliable, accurate emission results allow operators to optimise their equipment operation, ensure filter systems are working correctly, streamline cleaning systems, generate warnings and alerts, and minimise environmental impact. This all contributes to cost-effective operation while minimising the risk of faults that may lead to costly pollution clean-ups.

Core Capabilities

Synertec specialises in the design, construction, and commissioning of emission monitoring systems for industrial applications.

We design and install highly accurate emission monitoring systems to constantly sample and test environmental emissions.

Using the latest in smart technology, we configure threshold warnings and alarm systems to alert plant operators of approaching limits or triggered excesses.

Our systems include a streamlined reporting strategy to create emission performance reports in a variety of formats to satisfy the requirements of regulators and clearly communicate outcomes to management.

Focussed on Outcomes

As a team of specialist engineers, Synertec has an unwavering focus on solutions and outcomes.

We recognise that emission monitoring systems are a critical component of industrial installations and understand the importance of accurate monitoring for demonstration of critical compliance requirements.

Accuracy, consistency, and reliability are vital elements of emission monitoring systems and our focus on outcomes drives success on those key elements.

Examples

Emission monitoring systems can be utilised in a range of different industries, including:

- Liquefied Natural Gas (LNG) plants

- Bulk liquid terminals

- Petrochemical processing plants

- Industrial facilities

- Nuclear reactor plants

- Pharmaceutical manufacturing

- Waste incineration

- Any industry that emits controlled substances to atmosphere

Validation Capabilities

The term ‘Validation’ is broad in scope and reach. It may refer to a study demonstrating that a facility complies with relevant regulatory requirements, or it may refer to an exercise showing the qualification of a specific plant process against a particular standard, or it could relate to an investigation to confirm the test results of a flow monitoring system are accurate to within the required tolerances via a secondary testing regime.

Synertec is certified to ISO 9001 (Quality), ISO 14001 (Environment), and ISO 45001 (Occupational Health & Safety). We understand what it takes to develop and maintain compliant systems and to support our clients with their own performance and compliance requirements.

Our experience and knowledge are centred around a team of expert engineers and scientists who have a deep understanding of the technology and processes across a wide range of industries and have hands-on experience implementing compliant solutions for these industries.

With our extensive experience, we can identify and ‘translate’ the applicable regulatory requirements and standards that are best suited to the project and the organisation. Once the relevant standards are identified, Synertec can then implement a compliant strategy that is sustainable, risk based, cost-effective, and pragmatic, enabling a perfect fit solution for the organisation and the project.

Our experts in metering and sampling solutions understand the complex intricacies associated with high end monitoring systems and have calibrated many such systems to ensure their accuracy.

Track Record

Synertec’s areas of expertise include:

- Development and maintenance of compliant quality systems

- Continuous improvement planning

- Risk assessment and risk management

- Change management

- Training

- Audit readiness inspections and remediation planning/execution

- Process mapping

- Verification and validation of equipment, systems, and processes

- Design, construction, and qualification of cleanrooms and isolation suites

Metering and Sampling Solutions

- Flow Computing: A team of highly experienced metering engineers implement innovative, cost effective metering control systems

- Liquefied Natural Gas Custody Transfer: Synertec’s certified LNG custody transfer system ensures precise LNG load measurements

- Packaged Analyser Systems: On-line gas chromatography services

- Metering Skids: Complete turnkey metering solutions for a wide range of applications

- ISO 10723: Performance evaluation for analytical systems used in natural gas

Relevant experience

- Xepa Multi-Purpose Good Manufacturing Practice (GMP) Manufacturing Facility: Front End Engineering Design (FEED) study followed by detailed design and validation planning

- JAG Process Solutions Automation Control System Qualification: Independent validation and qualification for the automation control system for various major production plants

- CSIRO Manufacturing Facility for Inhaled Pharmaceuticals: Full service including advisory, FEED, detailed design, construction, and validation of a pharmaceutical manufacturing facility