Functional Safety

Functional Safety

- Functional Safety

Functional Safety Capabilities

We all understand the importance of safety in our lives and workplaces, but functional safety takes things to the next level. With a holistic, end-to-end perspective, functional safety considers all aspects of risk mitigation and the protection of people, assets, businesses, and the environment through the entire project lifecycle. Achieving functional safety means freedom from unacceptable risk of physical injury or damage to people’s health by the implementation of automatic protection and safety functions. Functional safety considers all elements of a system both individually and as a whole and is only achieved when every individual safety function performs to the level required.

TUV Rheinland provides the only worldwide Functional Safety training program where learning and capability are independently approved and certified. With TUV certified Functional Safety experts and engineers in-house, Synertec provides services covering the full lifecycle of a project or plant. We provide safety services to meet client needs from the definition stage through to implementation and then to the longest part of the lifecycle, being ongoing operation, maintenance, and auditing. Examples include:

Definition Stage

- Functional Safety management capability assessments

- Functional Safety assessments

- Safety Integrity Level (SIL) assessments

- Safety requirement specifications

- Concept design

- SIL verification

- System reliability studies

Project Stage

- Project lifecycle implementation

- SIL design and documentation

- SIL testing

- SIL validation

- SIL verification

Post Project Stage

- Ongoing maintenance

- Auditing of systems

- Management of change systems

- Decommissioning

Relevant Experience

Safety systems are found across most industries. Synertec can provide services in areas such as:

- Machine safety systems

- Burner management systems

- Emergency shutdown

- Fire and gas detection

- High integrity protection

- Pipelines

- Turbine safeguarding systems

- Wellhead control panels

- Safety Instrumented Systems (SIS)

Synertec engineers are well versed in the functional safety lifecycle activities as identified in standards such as IEC 61508 and 61511.

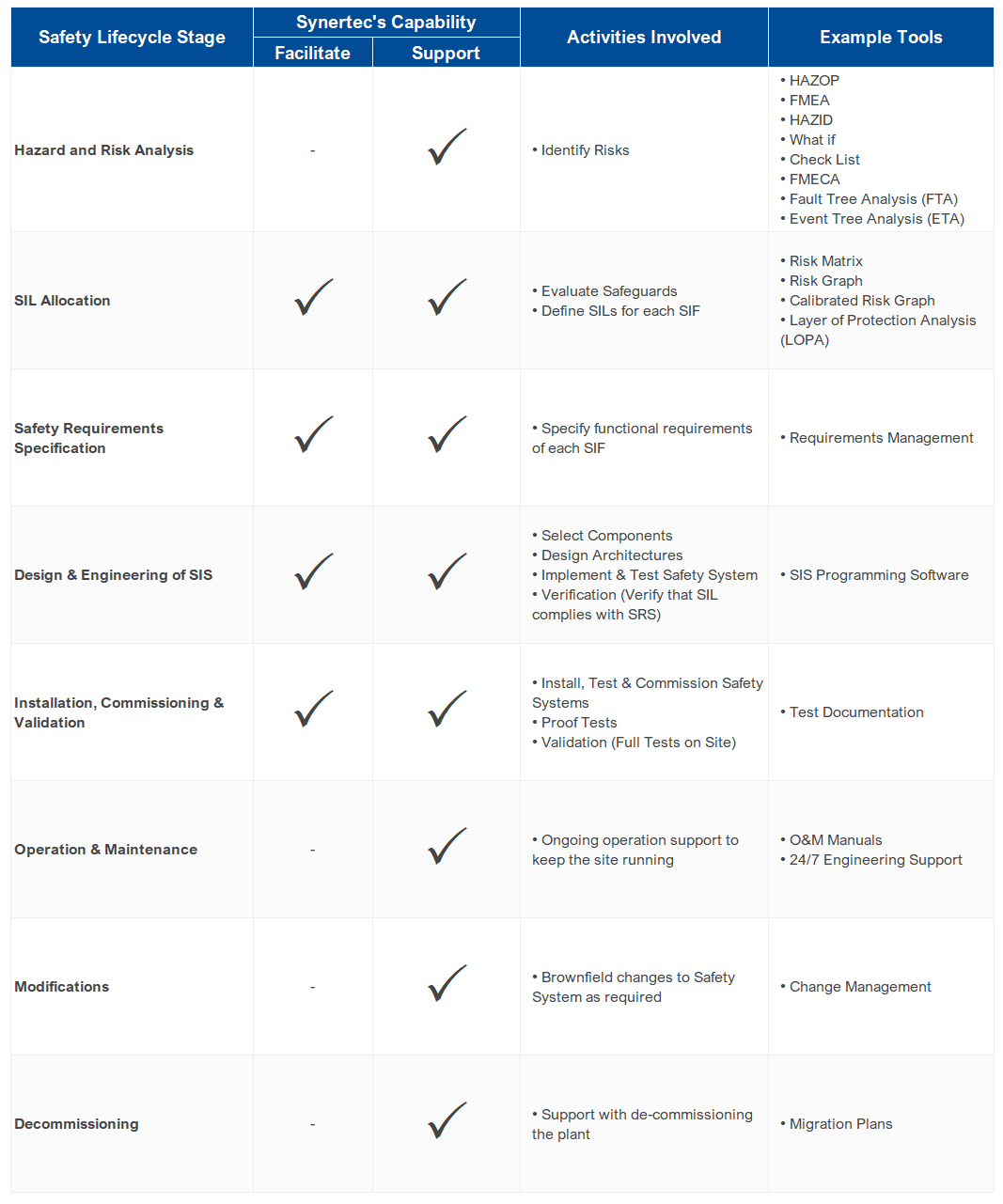

Synertec has the capability to provide support at every stage of the Safety Lifecycle. The table below provides a brief overview of our capabilities at each stage:

Synertec has capability in the following safety standards:

Standard | Title |

|---|---|

IEC 61508 | Functional safety of electrical/electronic/programmable electronic safety-related systems |

IEC 61511 | Functional safety - Safety instrumented systems for the process industry sector |

AS 4024 | Safety of Machinery |

AS 15288 | Systems and Software Engineering – System life cycle processes |

EN50126 | Railway Applications. The Specification and Demonstration of Reliability, Availability, Maintainability and Safety (RAMS) |

EN50128 | Railway applications. Communication, signaling and processing systems. Software for railway control and protection systems |

EN50129 | Railway applications. Communication, signaling and processing systems. Safety related electronic systems for signaling |