Process & Mechanical Engineering

Process & Mechanical

- Process & Mechanical Engineering

- Facility Design

- Modelling & Design Services

- Functional Safety

- Clean Room Design

Process & Mechanical Engineering Capabilities

Synertec has extensive experience and expertise in the process and mechanical engineering design of complex, critical systems. Synertec has the capability to scale up a process from the research bench to full production and works across various industry sectors and project sizes.

Synertec’s specialist capabilities include:

- Feasibility studies and preliminary project budgets

- Front End Engineering Design (FEED)

- Site master-planning

- Process and mechanical engineering

- Scale-up of new products and processes

- Modelling and optimisation of existing manufacturing operations

- Design, installation and commissioning of utilities including heating, ventilation, and air-conditioning, compressed gases, water, trade waste treatment, and other critical services

- High containment environments including Physical Containment (PC), Quarantine Containment (QC), and Bio Containment (BC)

- Hazard and Operability (HAZOP) studies

- Hazard Analysis Critical Control Point (HACCP) assessments

- Hazardous Area classification and design

Relevant Experience

Synertec’s Process & Mechanical Engineering expertise covers the following industries:

Facility Design Capabilities

Synertec’s process and mechanical engineers are experts in facility design, particularly of pharmaceutical facilities and clean rooms. Synertec has a team of process and mechanical engineers experienced in all phases of facility design from concept design through to commissioning and validation.

Our team works with our clients to understand facility requirements including process services, control systems, regulations, and compliance. Supported by an in-house design and drafting team, Synertec engineers fully document the facility design, including tender documentation for subcontractors and equipment suppliers and production of for-construction drawings for the facility build.

Our process and mechanical engineers are well supported by our automation and electrical teams to ensure all elements of the facility, including control systems, are incorporated in the design.

Our range of services is extensive, including the following:

- Process piping and tank design

- Facility layout, schematics, and architectural details

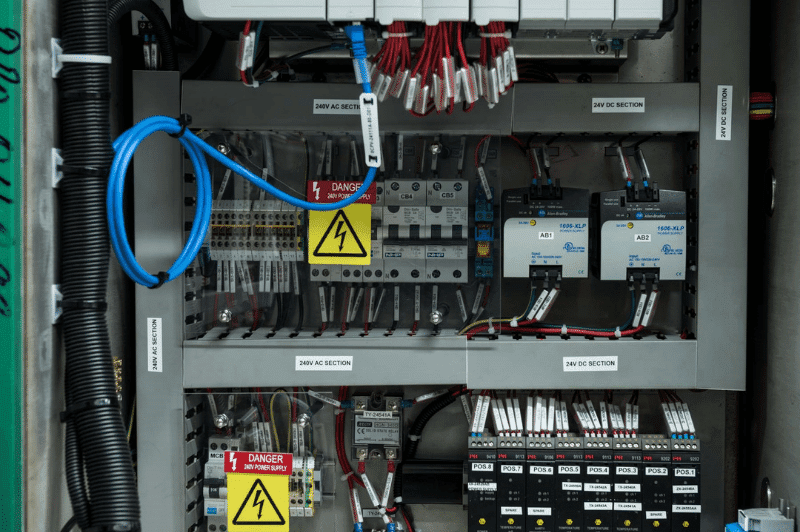

- Instrumentation and control system design, including safety control systems where required

- Process heating, ventilation, and air-conditioning, and heating / cooling system design

- Fire systems design

- Hazardous Area Classification reports for all areas of a building

- Advice on building requirements and constraints to support the architect and consulting engineers

- Piping and instrumentation design (P&ID) for the manufacturing and storage processes

- 3D modelling

- Specifications for pipes, valves, pumps, electrical equipment, etc. for all processes and services

- Tender documentation

- Risk management, change management, safety in design, Failure Mode and Effects Analysis (FMEA) and Hazard and Operability (HAZOP) studies

- Pricing estimates for facility construction

- Negotiations with statutory bodies and approval authorities such as the Environment Protection Authority (EPA), United States Food and Drug Administration (FDA), Australian Therapeutic Goods Administration (TGA), and more

- Coordination of town planning permits and building surveyor signoff

Relevant Experience

The facility design experience of Synertec’s engineering team includes work for the following clients:

- CSL

- Ego Pharmaceuticals

- Medical Development International

- Merck Sharpe and Dohme

- Pfizer

Modelling & Design Capabilities

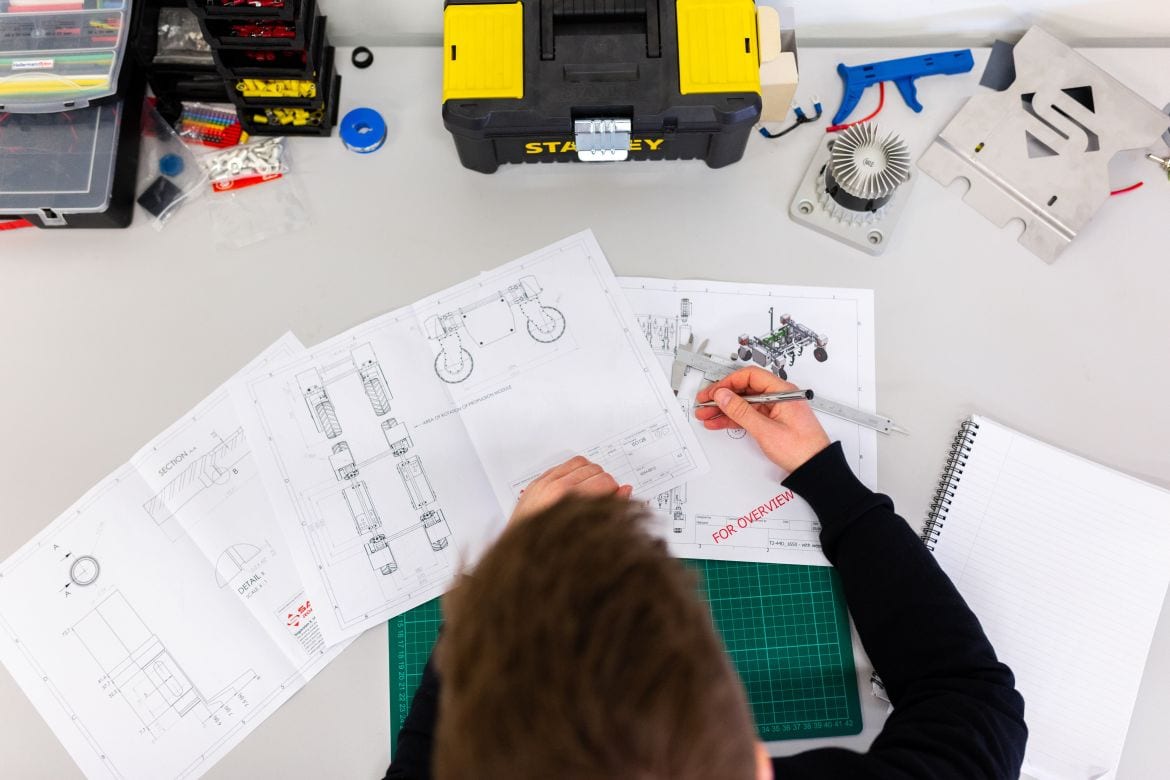

Synertec’s design office utilises a range of Computer Aided Design (CAD) packages including AutoCAD, Plant3D, and CADWorx. We work in both two-dimensional and three-dimensional design environments, depending on client and project requirements.

Our drafting practices comply with ISO 9001 and reference a library of drafting standards governed by applicable drafting procedures. Utilisation of document control software ensures a three-tier review process prior to drawing release. We have intelligent drafting tools to create smart Piping and Instrumentation Diagrams (P&IDs), which link the P&ID to the 3D model.

In conjunction with CADworx, we use Elecdes for electrical and instrumentation design. This ensures consistency between the P&ID, the 3D model, and the electrical / instrumentation database, allowing documentation such as instrument schedules, loop diagrams, line lists, equipment lists, and a bill of materials to be extracted from a single database.

Relevant Experience

Synertec’s designers are experienced with various design packages including:

- Plant 3D

- CADWorx

- Elecdes

- Revit

- Navisworks

Functional Safety Capabilities

We all understand the importance of safety in our lives and workplaces, but functional safety takes things to the next level. With a holistic, end-to-end perspective, functional safety considers all aspects of risk mitigation and the protection of people, assets, businesses, and the environment through the entire project lifecycle. Achieving functional safety means freedom from unacceptable risk of physical injury or damage to people’s health by the implementation of automatic protection and safety functions. Functional safety considers all elements of a system both individually and as a whole and is only achieved when every individual safety function performs to the level required.

TUV Rheinland provides the only worldwide Functional Safety training program where learning and capability are independently approved and certified. With TUV certified Functional Safety experts and engineers in-house, Synertec provides services covering the full lifecycle of a project or plant. We provide safety services to meet client needs from the definition stage through to implementation and then to the longest part of the lifecycle, being ongoing operation, maintenance, and auditing. Examples include:

Definition Stage

- Functional Safety management capability assessments

- Functional Safety assessments

- Safety Integrity Level (SIL) assessments

- Safety requirement specifications

- Concept design

- SIL verification

- System reliability studies

Project Stage

- Project lifecycle implementation

- SIL design and documentation

- SIL testing

- SIL validation

- SIL verification

Post Project Stage

- Ongoing maintenance

- Auditing of systems

- Management of change systems

- Decommissioning

Relevant Experience

Safety systems are found across most industries. Synertec can provide services in areas such as:

- Machine safety systems

- Burner management systems

- Emergency shutdown

- Fire and gas detection

- High integrity protection

- Pipelines

- Turbine safeguarding systems

- Wellhead control panels

- Safety Instrumented Systems (SIS)

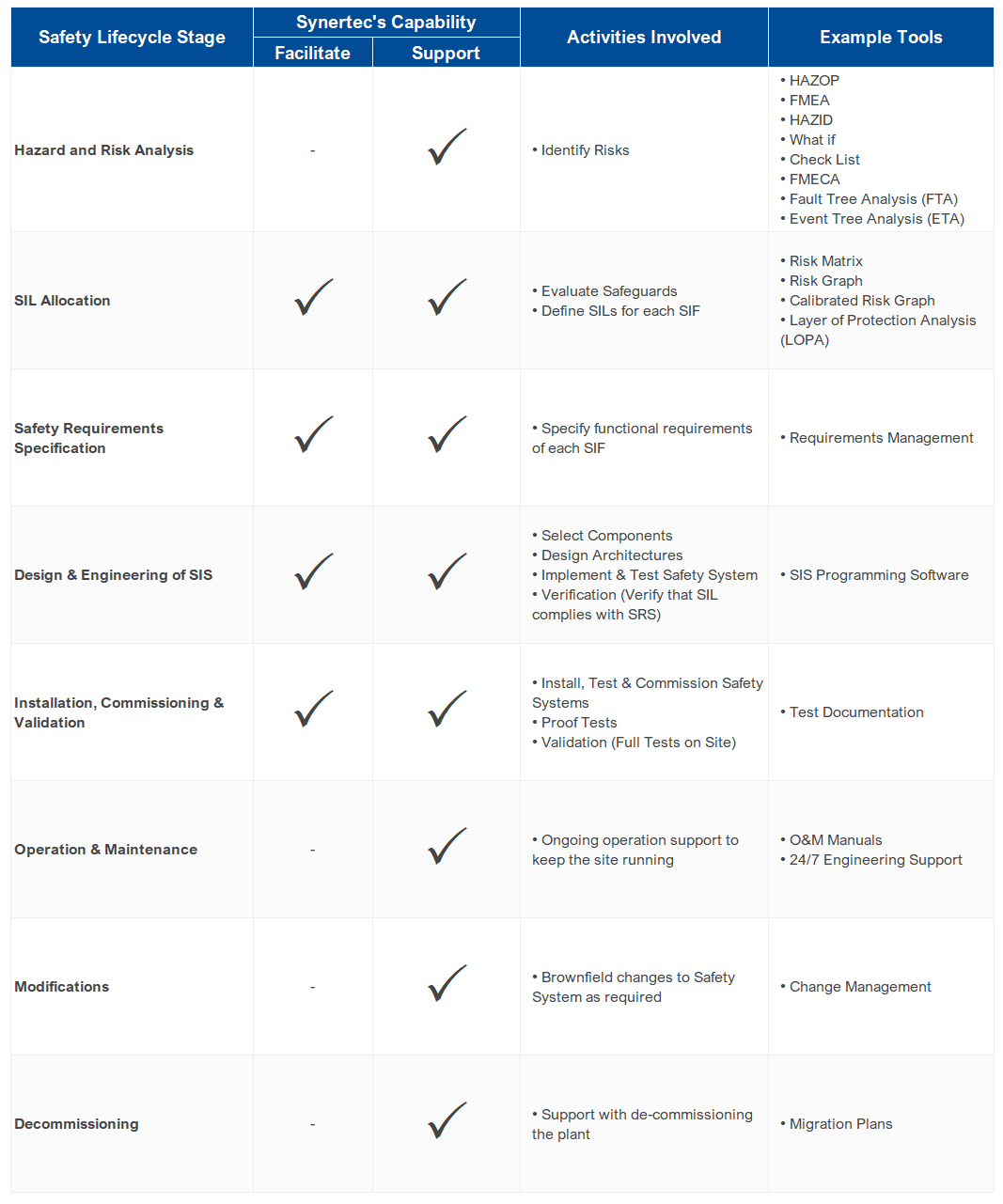

Synertec engineers are well versed in the functional safety lifecycle activities as identified in standards such as IEC 61508 and 61511.

Synertec has the capability to provide support at every stage of the Safety Lifecycle. The table below provides a brief overview of our capabilities at each stage:

Synertec has capability in the following safety standards:

Standard | Title |

|---|---|

IEC 61508 | Functional safety of electrical/electronic/programmable electronic safety-related systems |

IEC 61511 | Functional safety - Safety instrumented systems for the process industry sector |

AS 4024 | Safety of Machinery |

AS 15288 | Systems and Software Engineering – System life cycle processes |

EN50126 | Railway Applications. The Specification and Demonstration of Reliability, Availability, Maintainability and Safety (RAMS) |

EN50128 | Railway applications. Communication, signaling and processing systems. Software for railway control and protection systems |

EN50129 | Railway applications. Communication, signaling and processing systems. Safety related electronic systems for signaling |

Clean Room Capabilities

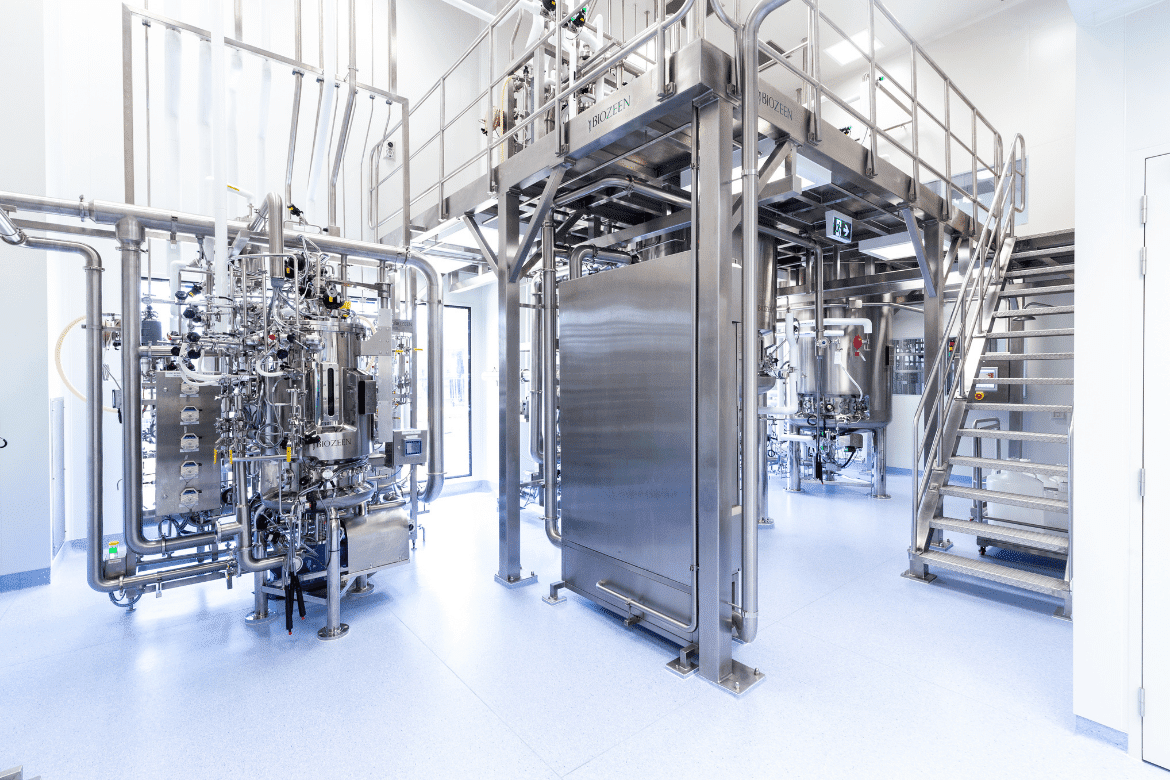

Synertec’s process and mechanical engineers are experts in facility design, particularly in pharmaceutical projects and clean rooms. Synertec has a strong, diverse team of process and mechanical engineers experienced in all phases of clean room design, from concept through to commissioning and validation.

Our team works with clients to understand the clean room requirements, from process services through to control systems, regulations, and compliance. Supported by an in-house design and drafting team, Synertec engineers can fully document the design of the clean rooms including tender documentation for all subcontractors and equipment suppliers, and construction drawings for the build.

The process and mechanical teams are strongly supported by the automation and electrical teams to ensure all elements of the clean room, including control systems, are incorporated in the design.

Core Capabilities

- Process piping and tank design

- Facility layout and schematics

- Instrumentation, safety, and control system design

- Process Heating, Ventilation, and Air-Conditioning (HVAC) systems

- Design of heating and cooling systems

- Fire systems design

- Hazardous area classification

- Advice on building requirements and constraints

- Develop piping and instrumentation diagrams for manufacturing and storage processes

- 3D modelling

- Specifications for pipes, valves, pumps, electrical equipment, etc.

- Tender documentation

- Risk management, change management, and safety in design

- Failure Mode and Effects Analysis (FMEA)

- Hazard and Operability (HAZOP) studies

- Pricing estimates for construction

- Negotiations with statutory bodies such as the United States Food and Drug Administration (FDA), the Australian Therapeutic Goods Administration (TGA), the Environmental Protection Authority (EPA) and more

- Coordination of town planning and building surveyor signoff

Focussed on Outcomes

As a team of specialist engineers, Synertec has an unwavering focus on solutions and outcomes. We recognise the importance of good design of clean rooms and understand the impact that poor design can have on operations and quality.

Consistency, safety, quality, and reliability are vital elements of clean room design and our focus on outcomes drives success on those key elements.

A recent example of a successful project outcome is Synertec’s work for Medical Developments International and the CSIRO on their manufacturing facility for inhaled pharmaceuticals. Compliance of the clean rooms was certified to meet the requirements of the TGA and the FDA, resulting in a successful FDA Audit and the issue of a license to sell product into the US market.

Relevant Experience

- Key clients: CSIRO, CSL, Ego Pharmaceuticals, Medical Developments International, Merck Sharpe and Dohme, Pfizer

- Biological Vaccines Manufacturing Facility: A suite for the manufacture of conjugated vaccines to meet FDA compliance and approval, with full High Efficiency Particulate Air (HEPA) filtration and containment zones

- Manufacturing facility for inhaled pharmaceuticals: Working with CSIRO and Medical Developments International for design, project management, construction supervision, and validation

- Bacterial fermentation facility: Upgrade of a facility manufacturing viral and bacterial vaccines for the animal sector

- Cytotoxic drug facility: Facility design for Pfizer’s Leap Frog facility in Melbourne specialising in cytotoxic drug products