Energy

Energy

- LNG

- Oil & Gas

LNG

Liquefied Natural Gas (LNG) is one of the fastest-growing segments in the energy industry. In just two decades the LNG trade has quadrupled in size and doubled its share of global natural gas trade, with Australia being one of the largest LNG exporters in the world. There are currently ten LNG production facilities in Australia, with five in Western Australia, three in Queensland, and two in the Northern Territory.

Synertec has been providing innovative solutions to the LNG industry for over ten years, commencing with flagship projects for the LNG plants at Queensland Curtis LNG and Australia Pacific LNG. We have worked with major LNG plants around Australia including Darwin LNG (DLNG), Gladstone LNG (GLNG), Gorgon, and Wheatstone.

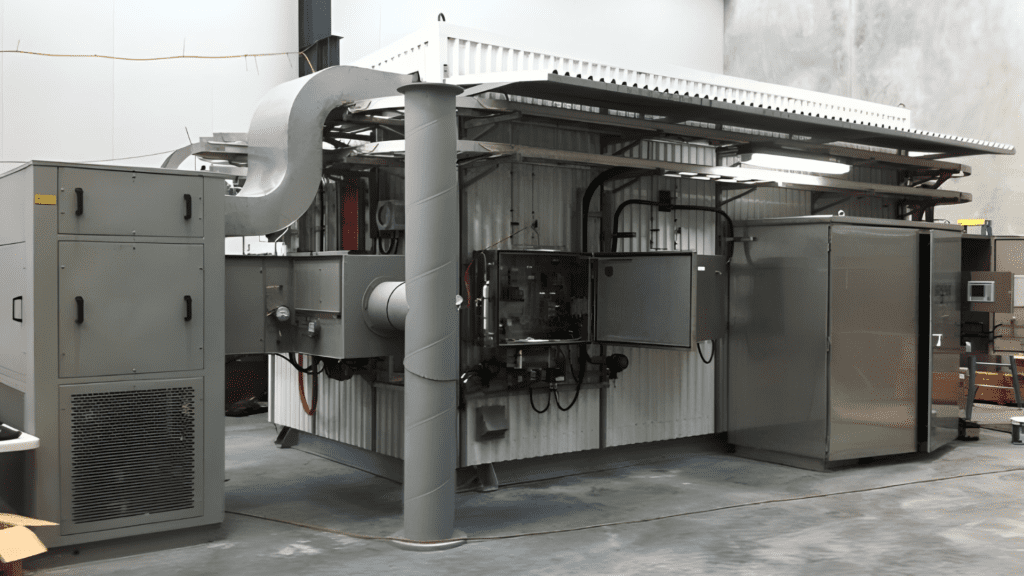

Synertec’s showcase product is the LNG Custody Transfer System, which is installed at both Wheatstone and Gorgon in Western Australia.

Core Capabilities

Synertec is uniquely positioned in the LNG industry with our innovative and best-practice design and build capability in Custody Transfer Systems.

We support clients with a multidiscipline engineering team covering the full lifecycle of services including concept design, detailed design, fabrication, testing and commissioning, maintenance, training, and operational support.

Synertec is not dependent on any particular platform or solution, so our teams can tailor the LNG solution to best suit the needs of the client and the project.

Relevant Experience

We have supported a wide range of clients including Chevron, ConocoPhillips, Bechtel, Santos, and Woodside to deliver a range of solutions. These include flow computing and control systems engineering and hazardous area, electrical, instrumentation and process engineering. We have delivered online gas-chromatography, analysers and sampling systems, housed in climate-controlled analyser houses and equipment rooms, shelters and wet racks.

Oil & Gas

Oil and Gas keep the world moving, forming a critical part of the global energy industry. Synertec is a multi-disciplined consulting practice providing specialist engineering services to the oil and gas industry. We are completely independent, with no ties or restrictions to specific vendors.

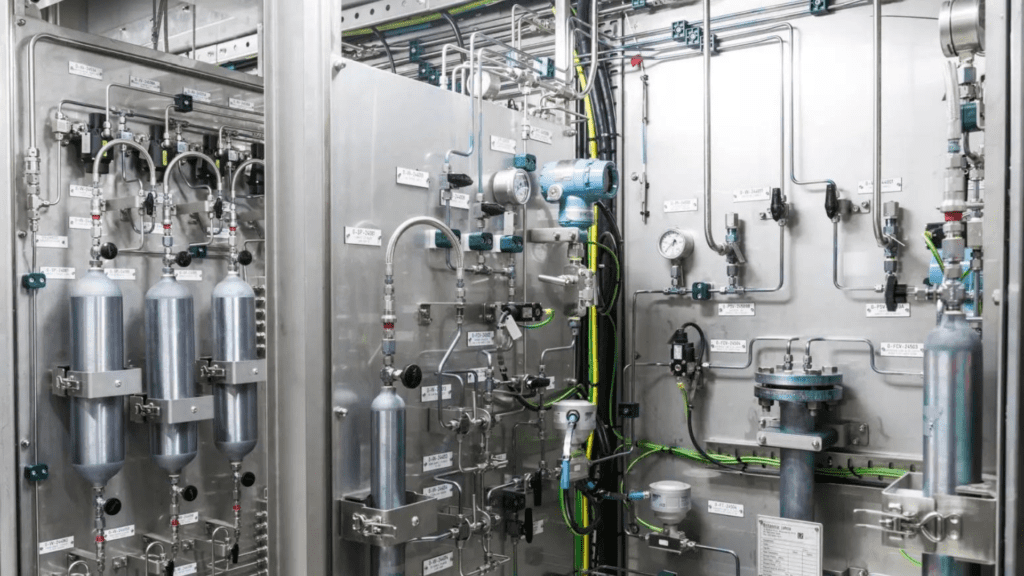

With large volumes of hydrocarbons – including natural gas, LNG, oil, and condensate – being transferred between buyer and seller, it is imperative that the measurement systems in place are of the highest precision and accuracy.

Synertec’s team of multi-disciplined engineers are dedicated to not only designing and implementing the most robust and reliable solutions, but also ensuring the ongoing accuracy of these systems through programs of regular validation, calibration, and servicing. Synertec specialise in the design, construction, commissioning, and validation of all types of metering systems. Our engineers are experts in flow computing, electrical, instrumentation, automation, functional safety, process, and mechanical engineering.

Synertec can design and build all elements of metering systems including:

- Metering skids

- LNG sampling

- Gas chromatographs

- Gas Analyser systems

- Flow computers

- PLC and SCADA systems

- Functional safety systems

Throughout the life of the asset, Synertec can assure accuracy and compliance of systems through these key consulting services:

- Meter Validation

- ISO10723 Gas Chromatograph Performance Evaluations

- System Audits

- Meter, Gas Chromatograph, and Instrumentation Servicing and Calibration

- 24/7 Support

Synertec consults with clients to formulate comprehensive and user-specific solutions in the Oil and Gas industry, ensuring solutions of complete security and control, with measurable real-time data to ensure quotas and demands are achieved with certainty and reliability.

We are accredited to ISO9001, ISO45001, and ISO14001 and are proud to deliver quality-assured results and innovative, practical solutions with high levels of safety and environmentally conscious outcomes that meet the requirements of our clients. We have a strong commitment to our projects and ensure all key decisions are made on a fully informed basis.

An example of our work in this sector is Jemena’s $800m Northern Gas Pipeline Project (NGP), where Synertec was engaged to design, supply, and commission the process control and safety system. We carried out the detailed design, including Hazard and Operability Risk assessment (HAZOP) and Control HAZOP, and supply of a large-scale programmable logic control automated system and flow computers, including electrical design and panel fabrication to meet the required functional safety standards. The system also included the combination of numerous plant packages and integration with Jemena’s Supervisory Control And Data Acquisition (SCADA) system to allow remote operations from Melbourne.

Core Capabilities

- On-line analyser design, fabrication, and integration

- Hazardous area classification and design

- Commissioning and maintenance

- Safety control systems for pipelines

- Service level agreements

- Spare parts

- Training