Critical Infrastructure

Critical Infrastructure

- Rail

- Water

- Bulk Liquid Terminals

Rail

Safety is of paramount importance to the rail industry, where milliseconds and millimetres can literally mean the difference between life and death. We provide premium quality safety control systems for the rail industry, including work on projects such as the Melbourne Underground Rail Loop (MURL), which runs under the central business district of Melbourne, Australia.

Synertec designed, supplied, and installed new technology to improve the MURL fire and life safety systems. Innovation was a key focus of the project, which was one of the first rail safety systems in Australia to use the Siemens Automation SIMATIC WinCC Open Architecture technology.

Core Capabilities

- Detailed design of hardware and software

- Factory acceptance testing and site acceptance testing

- Onsite installation without interruption to normal operations

- Functional safety engineering

- Assessments of Reliability, Availability, Maintainability, and Safety (RAMS)

- Cyber Security assessments

- Virtual Machine ware (VMware)

- Integration of video surveillance, security systems, and fire systems

- Human factors engineering

- System engineering including the V-model to represent a systems development lifecycle model

- Disaster recovery systems

- Simulation and training systems

Relevant Experience

Synertec has extensive experience in the rail sector, including key projects for the Melbourne Underground Rail Loop (MURL) and the new Melbourne Metro Tunnel Project, which are described below.

The MURL project for Metro Trains included a significant upgrade of the Supervisory Control And Data Acquisition (SCADA) control system architecture and IT infrastructure. The new SCADA system integrated numerous systems including programmable logic controllers, internet protocol video surveillance, security, fire, rail information, and building management. The project demonstrated Synertec’s ability to deliver within a tight schedule whilst ensuring zero-downtime of critical infrastructure, which is vital in a project of this nature.

Currently under construction, the Melbourne Metro Tunnel Project is one of the largest infrastructure projects in Victoria’s history. Working closely with the Rail Systems Alliance, Synertec delivered industrial control system design for the new control and monitoring system and associated installations, and Systems Engineering for further works related to the project.

Synertec works in compliance with key standards, including:

- EN50126

- EN50128

- EN50129

- SCADA UI development best practice – ANS/ISA 101.01-2015

Water

Protecting one of life’s most precious resources, the water industry is critical to survival and quality of life. We serve clients in the water sector through our expertise in design, construction, integration, commissioning, and operation of water projects, providing multi-faceted engineering skills across the entire spectrum of water solutions.

Synertec offers a range of engineering services within the water industries, including:

- Automation, instrumentation & control

- Functional safety engineering

- Process & mechanical engineering

- Construction management

- Water quality analysers (wet racks)

- Process analyser systems

Our skills in the water industry include industrial process control and automation, telemetry, electrical design, instrumentation design, project management, and 24/7 maintenance of complex operations and facilities. Solutions range from advice on a single topic through to complete turnkey delivery of a new facility.

Many of Synertec’s projects require work in live operational environments during the execution phase, for which we deploy comprehensive project management and leverage our extensive experience on brownfield sites.

Core Capabilities

- Design, development, commissioning, and qualification of distributed control systems, programmable logic controls, and Supervisory Control And Data Acquisition (SCADA) control systems, including Siemens WinCC, PCS7, Allen Bradley, ControlLogix, Citect, Wizcon / Axeda, Eurotherm 5180v, Rockwell RS View, GE Fanuc, Simatic, and OMRON

- Concept design of automation systems including Enterprise Resource Planning interface, Manufacturing Execution System, historian systems, network design, Programmable Logic Control design, Safety System interface, and telemetry systems

- Safety Instrumented System (SIS) Design & Integration

- Hazardous Area Classification & Design

- Construction Management

- Software development: C++, VB, SQL, XML, STEP 7, MOD300 TCL; MOD300 CCF, MS Access

- Selection and management of electrical subcontractors

- Supervision of site electrical works to AS3000

- Remote Terminal Units (RTU)

- Aspentech IP.21

- Automation and instrumentation water engineering

- Service Level Agreements (SLAs)

- Process & Mechanical Engineering

- Process Analyser Systems

- Functional Safety Systems

- Project Management

Relevant Experience

Synertec offers a comprehensive knowledge of processes such as:

- Ultra-Filtration (UF)

- Reverse Osmosis (RO)

- Ozone/Ultra Violet/Chlorine Disinfection

- Filtration/Aeration

- Aerobic & Anoxic environments

- Various post treatment concepts including chemical and natural processes

Our personnel bring operational and project experience from all facets of the water industry including small and large wastewater treatment plants and water desalination plants around Australia, including but not limited to:

- Victorian Desalination Plant

- Melbourne Water Eastern Treatment Plant

- South East Water

- City West Water

- East Gippsland Water

- Perth Desalination Plant

- Sydney Water

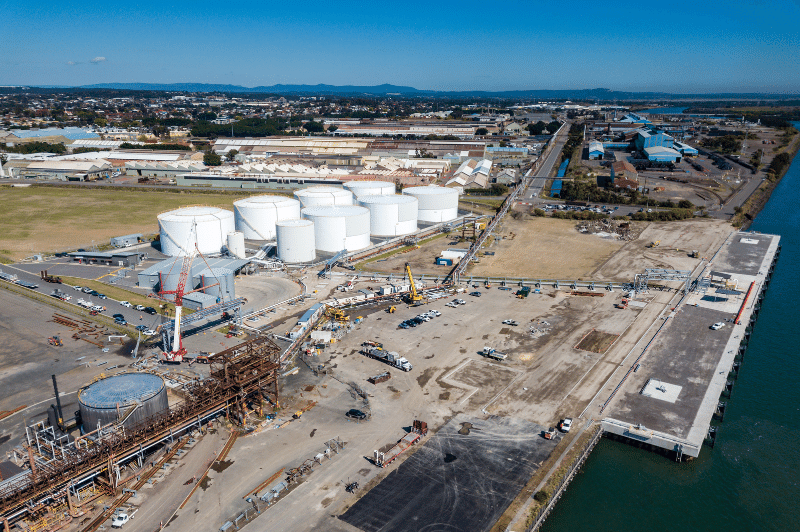

Bulk Liquid Terminals

Bulk liquid terminals are complex operational facilities for the storage of highly volatile and dangerous liquids. Extremely stringent safety standards are required, along with very specialised processes and handling procedures. These factors require a particular set of skills in the design and construction of these facilities.

We provide design and project management services to some of Australia’s largest independent bulk liquid terminal companies.

Synertec’s scope of terminal, tank, and piping design includes coordination of all design disciplines including electrical, civil, and structural. We assist the terminal project manager during the construction phase, generating all required drawings and documents for site measurements and managing the tender and trade contractors.

We support clients by designing and preparing the technical scope of work for establishment and regeneration, civil and waste treatment, process piping, fire suppression systems, electrical, instrumentation and security systems and road tanker filling.

Core Capabilities

- Process & mechanical engineering

- Automation & instrumentation engineering

- 2D & 3D drafting services

- Project management

- Construction management

- Functional safety engineering

- On-line analyser integration

- Service level agreements

- Hazardous area classifications & design

- Hazard and operability study (HAZOP) facilitation

Relevant Experience

We have a wealth of experience in bulk fuel construction projects, offering innovative solutions that showcase the team’s design, installation and consultation capabilities while achieving client expectations, timeframes and budgets.

Synertec has worked with some of Australia’s largest independent liquid terminal companies including Shell, Stolthaven, Terminals Pty Ltd and the Department of Defence.