Electrical & Instrumentation Engineering

Electrical & Instrumentation

- Control Panels

- Local Equipment Rooms

- Hazardous Area Design

- Online Analysers

Control Panel Capabilities

Control panels are the brains of industrial systems, collecting inputs from sensors and sending instructions to equipment to adjust operating parameters that keep the systems running at peak capacity. A critical component of any system, control panels require special design and construction to ensure compliance with operational standards and certification requirements. Synertec offers a wealth of experience in control panel services including design, delivery, installation, and testing. Our control panel services ensure industry-wide compatibility while complying with important client requirements of program and budget.

Control Panel Delivery Process

The first step in the delivery process is for our team of multi-discipline specialist engineers and drafting personnel to complete the design, documentation, and approval of the control panel. Next comes fabrication, for which we leverage our close working relationships with various panel fabricators including ADX, Decon, ARA, and Trivantage. During the build stage, our experienced team ensures thorough inspections and extensive testing, and we completely manage all elements of cost, program, and subcontractor time.

Upon completion of fabrication, Synertec performs early stage Factory Acceptance Testing (preFAT), involving a complete test of the system where all defects are identified and rectified. This is followed by a final, client-witnessed Factory Acceptance Test (FAT). The control panels are then packaged and delivered to site, where Synertec manages the installation in the final location.

Upon successful final installation, Site Acceptance Testing (SAT) is then conducted including full point-to-point testing and hardware checks, after which a test report and defects list is issued to the client. Synertec then manage the resolution of any final defects with the supplier, with the last step being final signoff by the client.

Hardware Design Capabilities

Synertec’s hardware design capabilities include the following:

- Electrical control panels

- Communication cabinets

- IT server cabinets

- Instrumentation

- Remote operator panels

- Junction boxes

- Local equipment rooms, including heating, ventilation, air-conditioning, uninterruptable power supplies, fire suppression systems, etc.

Deliverables

The deliverables on a control panel project vary depending on client requirements, but typically include the following:

- General arrangement drawings

- Termination diagrams and cable schedules

- In / Out lists

- Bill of materials

- Power and earthing schematics

- Heat load calculations

Local Equipment Room Capabilities

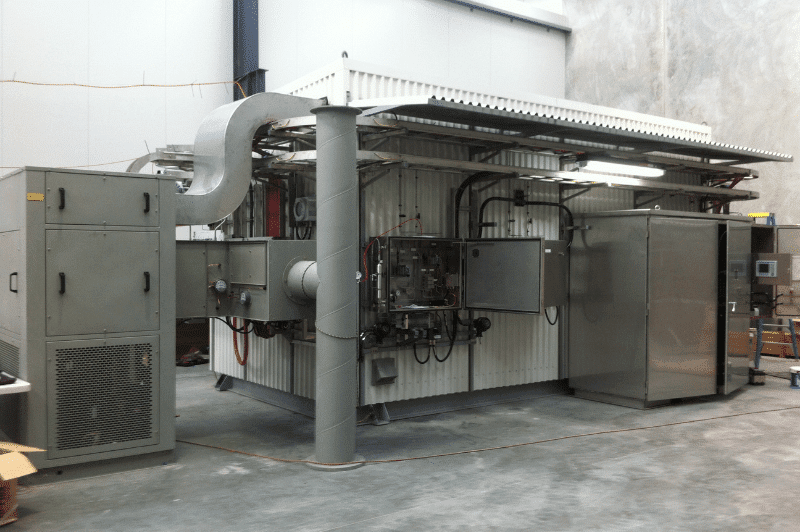

Synertec specialises in the design, construction, and commissioning of Local Equipment Rooms for industrial applications.

Our extensive experience with equipment rooms of all scales ensures that our designs and our builds comply with the strict regulatory environment of the specific industry and achieve the highest of safety standards. Many Synertec projects involve complex fabrication, electrical works, and instrumentation for the most demanding of customers.

Synertec’s capabilities in the design and fabrication of equipment rooms includes not only the structure but also all the internals including heating, ventilation, air-conditioning, motor control centres, control panels, electrical fitout, and more. As a firm of multi-discipline specialist engineers, Synertec can provide all necessary services comprising deliverables from all engineering disciplines including civil, structural, mechanical, process, electrical, instrumentation, and control systems.

Core Capabilities

Our engineers provide the full suite of design services for these projects including:

- Foundation and support plans

- Structural support calculations

- Floor plans

- Concrete works

- General arrangements

- Services layouts

- Chilled water and heating water schematics

- Electrical schematics and wiring diagrams

- Lighting and fire detection layouts

- Power and communication layouts

- Switchboard heat dissipation calculations

- Technical specification documents

- Cabling drawings and schedules

- Control panel layouts

Focussed on Outcomes

As a team of specialist engineers, Synertec has an unwavering focus on solutions and outcomes. We recognise that local equipment rooms are a critical component of industrial installations and understand the impact that even a few minutes of downtime can cause.

Safety, security, service, and reliability are vital elements of local equipment rooms and our attention to outcomes drives success on those key elements.

Our focus on outcomes and our multi-discipline team of specialist engineers provides our clients with holistic, integrated solutions for local equipment rooms that function effectively and efficiently.

Examples

- A gas flow measuring equipment room in a liquefied natural gas plant

- A communications equipment room on an offshore oil rig

- A monitoring equipment room in a chemical plant

- An electrical equipment room in a bulk liquid terminal

- A gas analyser equipment room in a gas plant

- A server equipment room in an industrial factory

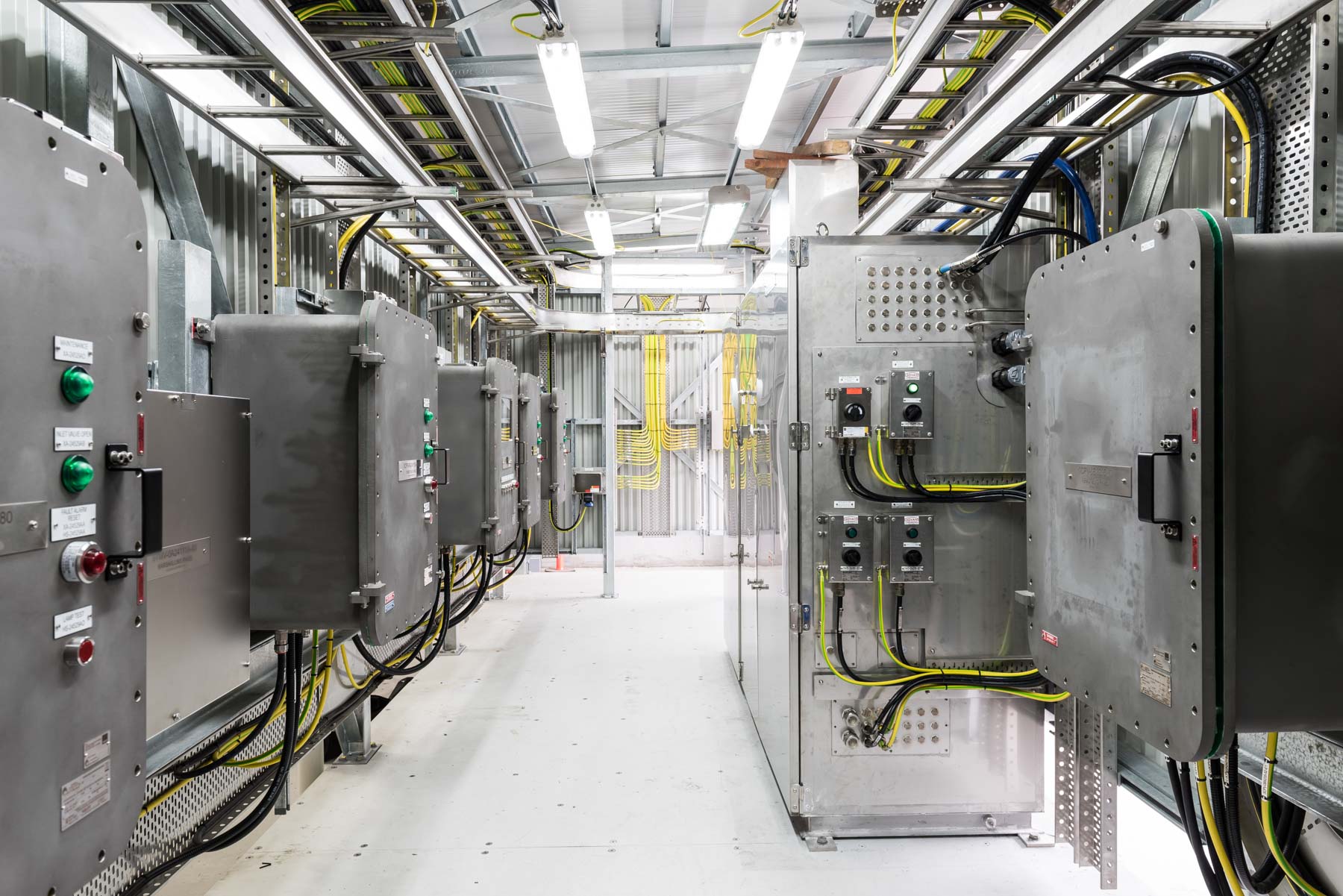

Hazardous Area Design

A hazard is not necessarily dangerous. Provided the hazard is identified and controlled with appropriate safety measures, the danger associated with a hazard can be eliminated or reduced. This is where Hazardous Area Design comes in. If the atmosphere in the area is or may have the potential to be explosive, then special precautions are required for all electrical equipment. Key elements to be considered include the type of flammable zone, gas grouping, amount of vapour or dust present, ventilation, explosive limits, and temperature classes. Electricity can only be connected to a zone if all hazardous areas have been identified and documented in a Hazardous Area Dossier.

Classification of Hazardous Areas involves a prescriptive, regulated, and controlled assessment of zones and hazards. Safety risks such as flammable goods, combustible dusts, and pressurised vessels are identified to establish potential explosion risks. All areas within a facility such as a plant or factory are thoroughly examined and then zoned according to the potential hazards contained within that zone. Once the hazards are identified, safety measures and control systems are implemented to mitigate the hazard, thereby reducing the associated danger and increasing the safety level for people, the plant, and the environment.

Core Capabilities

- Plant design

- Area classification

- Selection of appropriate explosion protected equipment

- Installation of equipment with suitable cabling, installation practices, etc.

- Commissioning and test verification

- Maintenance schedules

- Hazardous area dossier

- Overhaul, repairs, and maintenance

- AS/NZS 3000: Electrical wiring rules

- AS/NZS 60079: Requirements for the design, selection, and installation of electrical equipment in hazardous areas

Experience

Assessment Methodology

- Identify potential sources of release of flammable gas or vapour, or combustible dust

- Classify the area as Zone 0, 1, or 2 depending on the likelihood and extent of explosive gas presence

- Consider factors such as temperature, pressure, dispersion, nature of flammable material, ventilation, probability of release, etc.

- Nominate requirements for electrical equipment, e.g. intrinsically safe ia / ib, flameproof enclosure d, special protection Ex s, increased safety, Ex e, etc.

- Assign temperature classification

- Identify ignition sources

- Consider special factors such as lightning protection

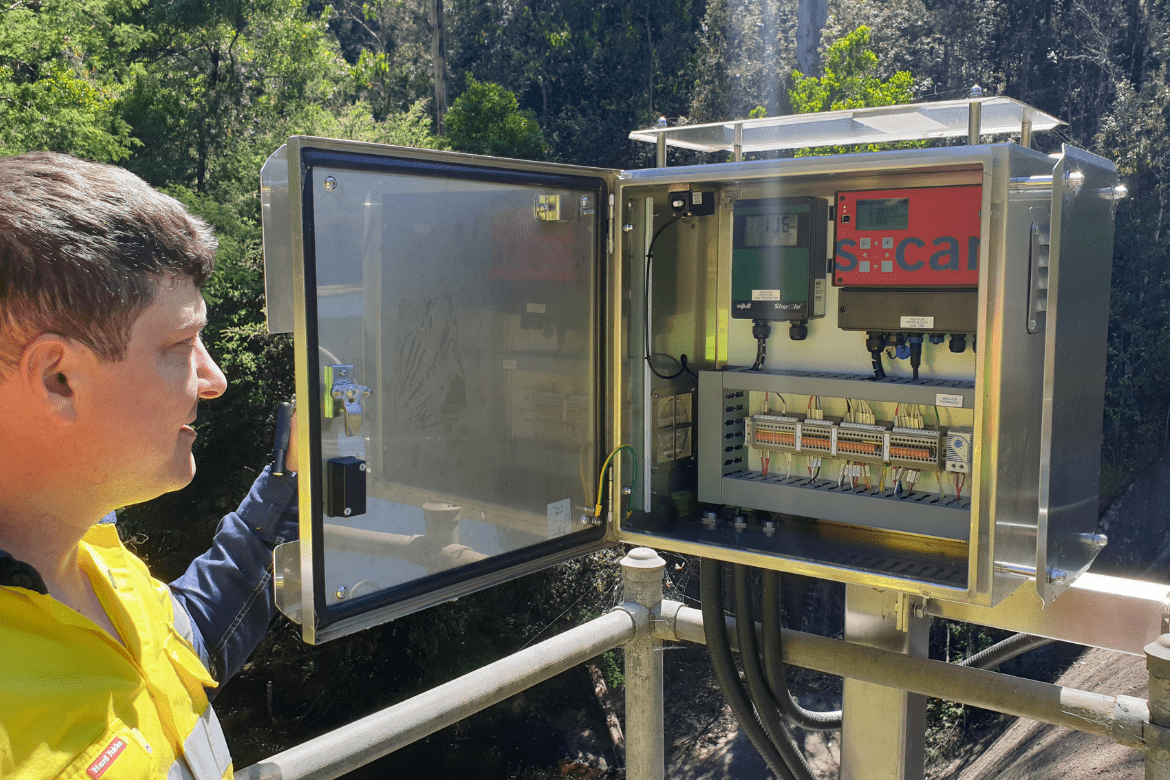

Online Analyser Capabilities

The use of online analytical instruments is becoming more and more important as customers strive to increase the quality of goods, reduce costs, and meet regulatory requirements. Synertec can provide vendor independent engineering services to ensure the total system meets all requirements and achieves high value for money outcomes.

A successful implementation can be assured by using Synertec to provide a complete end-to-end solution.

Focussed on Outcomes

Implementing a reliable online analyser system is a complex undertaking that is about so much more than simply choosing an analyser. The success and ongoing reliability and accuracy of the measurements require holistic integration of the entire system. This includes the design of the sample probe or extraction system, sample transport, conditioning and phase control, presentation to the analyser, and then finally the safe and environmentally responsible disposal of the sample.

Synertec has the analyser system experience to ensure this is incorporated into every instrumentation system design. We design and build gas chromatograph systems, analyser houses, and flow computers to gather this key data. To ensure ongoing accuracy of the system, Synertec can perform validation and calibration services, including ISO10723 performance evaluation on all instruments.

The analyser environment plays a major role in the reliability of an online analyser solution. Synertec can specify, design, and build a suitable and cost effective solution for any environment. Typical approaches include a simple cabinet, an intermediate shelter, or a complete housing, for either safe or hazardous environments.

Track Record

Synertec provides services for the following typical applications:

- Online gas chromatography for natural gas, Liquefied Natural Gas (LNG), and hydrogen

- Custody transfer

- Continuous Emissions Monitoring Systems (CEMS)

- Hydrogen cooled generator

- Gas purity

- Calorimeter systems

- Physical property analysers

- Humidity systems

- Infrared analysers

- Wet racks

Relevant Experience

- Design and supply of 45 analysers including GC, CO2 and moisture analysers for Queensland Curtis LNG, including the design and build of 5 analyser racks and 8 analyser shelters

- Design and supply of six fully air conditioned analyser shelters with fire and gas systems for a Zone 2 hazardous area for Australia Pacific LNG. These shelters contained GC, Wobbe, moisture, CO2, O2, and water analysers, along with flow computers and LNG samplers

- Active ventilation and off-gas control system for a nuclear waste treatment facility at the Australian Nuclear Science and Technology Organisation (ANSTO) nuclear reactor facility at Lucas Heights